VOC Reduction System for Crude Oil Loading Operations

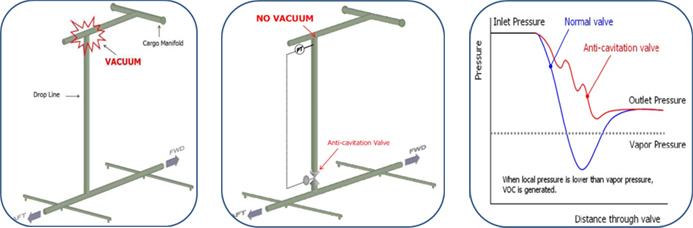

During crude oil loading, the pressure at the top of the drop line is often lower than ambient pressure because the vertical height generally exceeds 20 m and can reach 27 m for VLCCs. When this pressure drops below the True Vapor Pressure (TVP) of the crude oil, vaporization occurs and Volatile Organic Compounds (VOC) are generated.

As the flow enters the tank bottom, part of the VOC is re-condensed through pressure recovery. However, due to the lack of thermal equilibrium, complete re-condensation is impossible, and uncondensed VOC is released into the atmosphere — leading to both environmental impact and economic loss. Depending on the cargo condition, approximately 50 – 200 tons of VOC may be emitted per vessel during loading.

The DE-VOC System developed by JangWon SM Co., Ltd. minimizes VOC emissions by optimizing pressure recovery and condensation efficiency throughout the loading process.

Reference Projects

| No. | Client | Vessel / Project | Class | Status | Remarks |

|---|---|---|---|---|---|

| 1 | Bergesen Worldwide | 1 Ship – BW NYSA | Lloyd’s Register | In use: Dec 2009 – Nov 2013 | Demo Project / Withdrawn after trial |

| 2 | Kuwait Oil Tanker Company | 4 Ships – 317,000 DWT Crude Oil Tankers | ClassNK (Project base approval) | In use since Apr 2014 (DSME H5389 – H5392) | |

| 3 | Kuwait Oil Tanker Company | 1 Ship – 110,000 DWT Aframax PC | ClassNK (Project base approval) | In use since Jul 2014 (DSME H5393) | |

| 4 | KE1614 “PIONEER” (156K Suez-Max COT) | Lloyd’s Register (Project base approval) | Contracted – Design Phase | Builder: Navantia (Spain) / EP Provider: DSEC |