VOC Reduction System

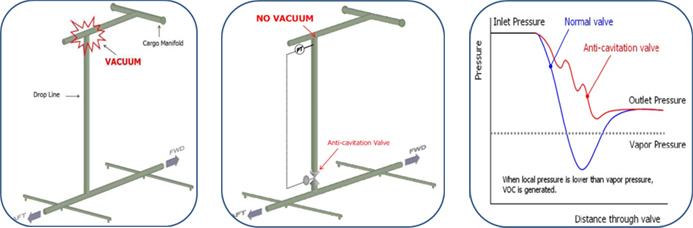

The crude oil pressure at the top of loading line is less than ambient pressure since the drop line height is generally lager than 20m and it is up to 27m for VLCC. If the pressure is less than TVP(True Vapor Pressure) of the crude oil, the oil starts to boil and the VOC will be generated.

The generated VOC can be re-condensed by the pressure recovery according to flow into the tank bottom, full re-condensing is not possible since thermal equilibrium is not maintained in the tank. The non re-condensed VOC emits from the vessel causes environmental problem and economical loss also. It is known that 50~200 ton of VOC emits per vessel during loading depending on cargo conditions.

REFERENCE LIST

| SN | CLIENT | NUMBER & NAME OF SHIP | CLASS | Project Status | REMARKS |

| 1 | Bergesen, Worldwide | 1 SHIP – BW-NYSA | Evaluated by

LLOYD’S REGISTER | In use: Dec. 2009 ~ Nov. 2013 | *Demo Project

**Withdrawn after Demonstration |

| 2 | Kuwait Oil Tanker Company | 4ships – 317,000DWT

Crude Oil Tanker | ClassNK

(Project base approval) | In use: From April 2014 | DSME H5389 ~ H5392 |

| 3 | Kuwait Oil Tanker Company | 1ships – 110,000DWT

AFRAMAX PC | ClassNK

(Project base approval) | In use: From July 2014 | DSME H5393 |

| 4 | KE1614 | “PIONEER”, 156K

Suez-Max COT (Standard: 4ships / Option: 2ships) | Lloyd’s Register of Shipping

(Project base approval) | Construction status:

Contracted and just Design started | Builder: Navantia, Spain

EP provider: DSEC |