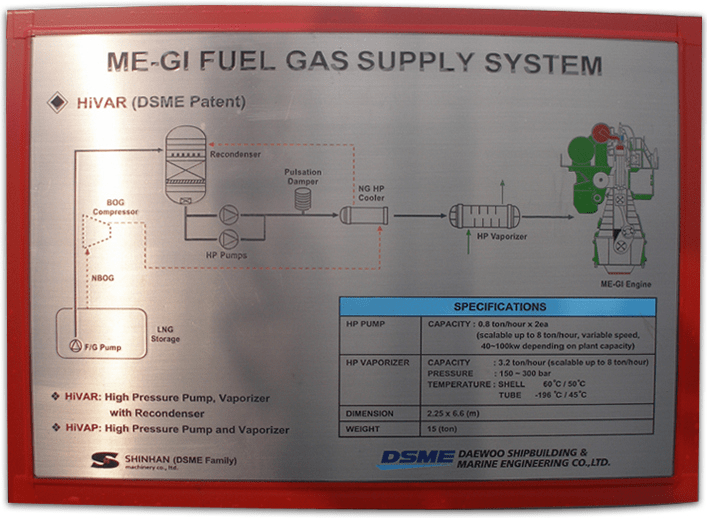

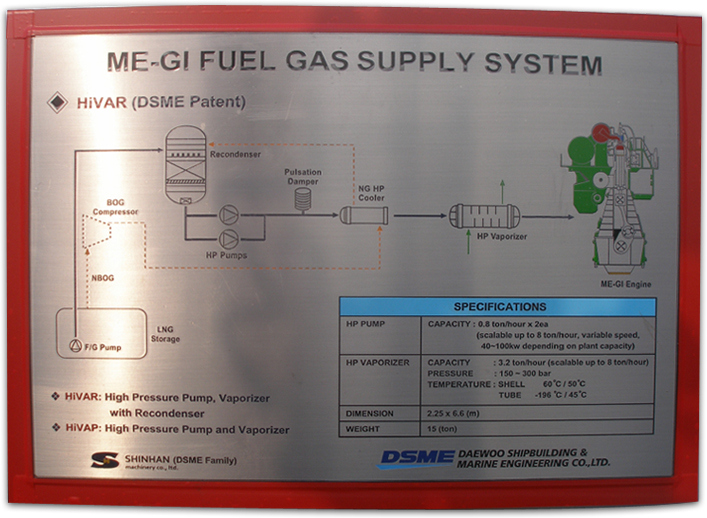

Fuel Gas Supply (FGS) System

High-pressure LNG vaporization and fuel delivery system for ME-GI engines

The Fuel Gas Supply (FGS) system supplies vaporized LNG fuel to the main ME-GI engine through a high-pressure and precisely controlled process. It consists of a suction drum, high-pressure pumps, high-pressure vaporizers, a glycol-water (GW) heating system, and high/low-pressure piping and valves.

LNG stored in the tank at 2.5–8 bar(g) is fed to the suction drum, where pressure is maintained slightly lower than the LNG tank pressure. The liquid is then pressurized by the high-pressure pumps and sent to the HP vaporizer. Inside the vaporizer, LNG flows through the tube side while heated glycol-water circulates in the shell side, enabling efficient vaporization. The resulting natural gas is supplied to the ME-GI engine for combustion.

System Configuration

- FGS Skid (Hazardous Area): Suction drum, high-pressure pumps, HP vaporizer

- GW Skid (Non-Hazardous Area): Glycol-water tank, feed pump, electric heater

The suction drum serves as a buffer tank for stable operation. The high-pressure pumps raise LNG pressure to approximately 150–300 bar(g), and the vaporizer heats the pressurized LNG to the design temperature of 45 °C, ensuring reliable gas supply for the ME-GI engine.

Related keywords: LNG fuel, marine engine, ME-GI, fuel gas supply, vaporizer system